Wendy Mclellan

Province

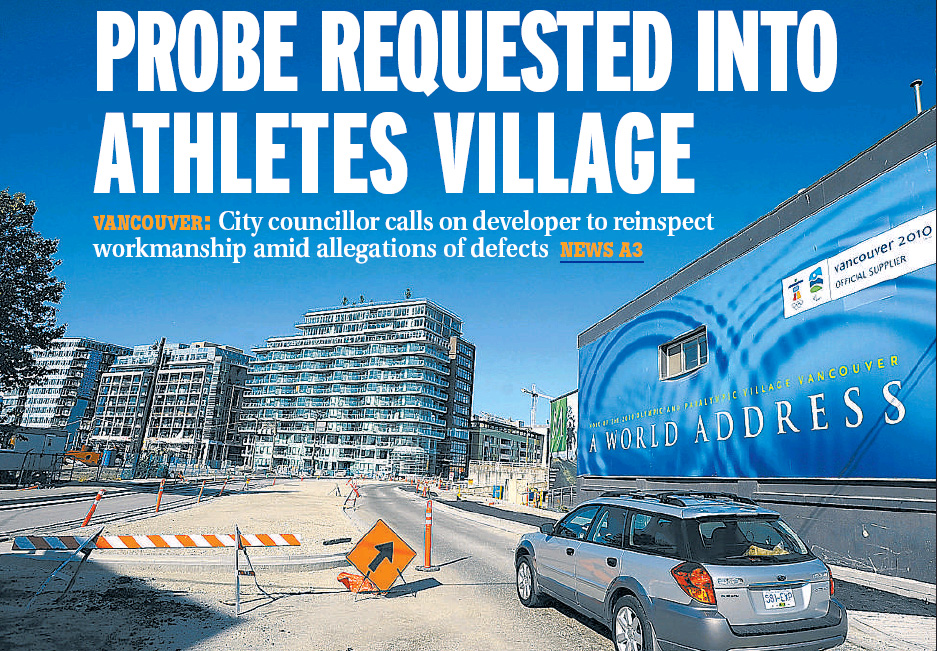

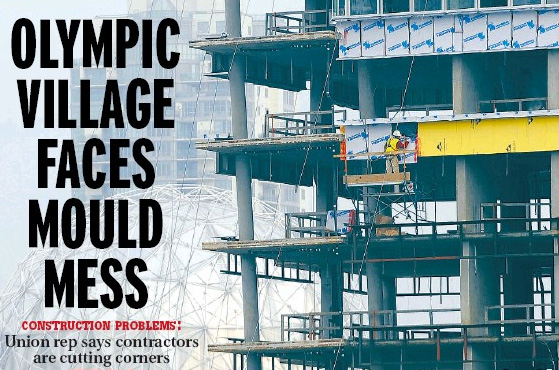

The Olympic Athletes Village under construction at False Creek. Photos indicate some of the pipes are being installed without insulation. GERRY KAHRMANN – PRIVINCE FILE PHOTO

The Olympic Athletes Village under construction at False Creek. Photograph by: Gerry Kahrmann, Province File Photo

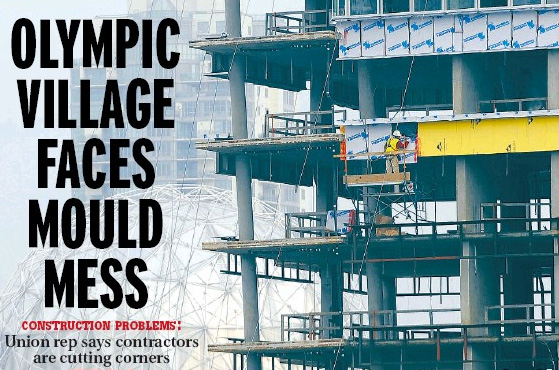

Lee Loftus, business manager for the International Association of Heat and Frost Insulators and Allied Workers Union Local 118, says the pipes are not being properly insulated, which could lead to mould and mildew problems, as well as a lack of energy efficiency.

A photo inside the new Woodward development shows a set of properly insulated pipes — HANDOUT

An example of uninsulated water pipes inside the walls at the Olympic village. Drywall has been installed over bare pipes – HANDOUT PHOTO

Vancouver‘s Olympic Athletes Village is being promoted — and sold — as one of North America‘s most energy-efficient, green communities, but tucked away behind the new drywall are the ingredients for a mouldy, energy-leaking mess.

The “model for sustainable development” has been built without insulation that is supposed to completely wrap hot and cold water pipes. Insulation reduces energy loss from the hot water pipes; it also prevents condensation from pooling around the cold water pipes, where it can turn into mould and mildew.

The problem won’t be visible until long after the athletes have left, but in about three years condo owners will begin to notice the tell-tale signs of a situation that may cause health problems for some residents as well as a financial nightmare to fix.

“We know the water will be pooling inside the walls, but it won’t show for 18 months or a little longer,” said Lee Loftus, business manager for the local union representing mechanical insulators.

Loftus and a colleague from the International Association of Heat and Frost Insulators and Allied Workers Union Local 118 have taken photographs of the bare pipes in several buildings on the Southeast False Creek site under development by Vancouver‘s Millennium Group.

The photos show drywall installed over uninsulated pipes in several buildings. Some pipes are insulated where they are visible outside the walls; others are mostly insulated. In some areas, the drywall had already been completed so there was no way to see whether the pipes were properly wrapped.

Millennium Southeast False Creek Properties Ltd. is paying engineers and consultants to inspect the development that is supposed to meet LEED gold standards, a designation for buildings that meet high standards for energy and water efficiency, indoor air quality and sustainability. But the partially uninsulated pipes will mean lost heat and efficiency, and air quality will suffer when mould and mildew grow, Loftus said.

“There’s nothing green about that,” he said. “These people think they’re buying something well-made and green, but they’re not getting what they’re paying for — and the developer isn’t getting what they’re buying.”

GM says problem fixed

Loftus said he met with Hank Jasper, general manager of development and construction for Millennium, six weeks ago and showed him the photos.

Jasper acknowledged he met with Loftus as well as representatives from other trade unions, and that he was given photos of improperly insulated pipe. But he said only one photo taken in a parking garage showed a problem, and it was fixed.

“They pointed out, I think in one location in one parcel, that there was a temporary piece of insulation that had been put on a piece of pipe that we dealt with immediately,” Jasper said in an interview Friday.

He said the site is being monitored and inspected by various inspectors, contractors and engineers and drywall could not be installed before every pipe was properly insulated.

The photos tell a different story. Jasper said he is not familiar with any photos other than the one taken in a parking garage.

“There’s no location I’m aware of where that has occurred and there’s no way that could happen anyway, because all of the suites, all areas, before any board is applied, inspections take place,” Jasper said. “No boarding can proceed without those sign-offs by inspectors. Every suite gets checked.”

At least five mechanical insulation companies — both union and non-union — are working as subcontractors on the site, and the development is so large inspectors may not see problems, says Loftus. He said he had hoped Millennium would have responded quickly to concerns about quality control, but after waiting for weeks, he decided to go public.

“They [the subcontractors] are cutting corners, and I will bet that the savings aren’t flowing back to the developer,” Loftus said. “The developer is spending money for LEED standards and they should get what they paid for.”

$450 m and counting

The city has already invested more than $450 million in the development that is supposed to provide a mix of market and social housing. The City of Vancouver is also financing the $1 billion project, after buying out Fortress Investment Group earlier this year.

The city retains ownership of the land during construction and expects to recoup its investment when the units are sold or rented.

Loftus said B.C. Building Trades Council organized a meeting between various trades representatives and Millennium Group on May 11. Wayne Peppard, executive director of the trades council, said he had approached Vancouver city councillor Geoff Meggs with some concerns about subcontracting at the development and Meggs suggested he speak with city manager, Dr. Penny Ballem. Ballem advised the trades to meet directly with the developer.

During the meeting, Loftus says, Jasper was shown photos of the uninsulated pipes in various buildings on the site and said he would get back to the insulators union, but Loftus said he’s still waiting. A second visit to the site weeks after the meeting found the drywall still in place with the pipes now hidden behind it.

“I don’t think they can fix it on time,” Loftus said. “They would have to take the walls down, inspect all the piping and then do it right. It would certainly be cheaper to do it now rather than later, but I’m guessing it would cost millions.

“And if they found mould, it would be even worse.”

Ballem said she wasn’t told about any specific problems with the construction of the Olympic Village, only that a union had some concerns about quality control.

“This is the first I’ve heard of this,” Ballem said when contacted by The Province. “If the concerns are true — and I have no evidence of whether they are or not — and they not being paid attention to, that’s a concern for the city.”

She said she will direct the city’s project manager assigned to the Olympic Village development to consult with Millennium about the issue.

“Clearly this is a major concern for the developer because they will own the vast majority of the project — it is their development,” Ballem said.

“To have a newspaper article saying we’re building leaky condos is not great for anybody.”

Campbell confident

Senator Larry Campbell, who purchased two units at Millennium Water, didn’t know about concerns over the pipe insulation but said he’s confident the developer will fix any deficiency.

“I’m not concerned about it,” Campbell said. “I have complete faith in the developer — I wouldn’t have bought there if I didn’t. I’m looking forward to moving in.”

He did say he intends to check into the issue.

A common problem

Andre Pachon, president of the B.C. Insulation Contractors Association, said contractors often bypass the building specifications that require insulation around pipes as a way to save time and money. He has ripped out ceilings in municipal and residential buildings to repair damage caused by condensation dripping from cold water pipes, and added insulation to hot water pipes that were left bare while cold water pipes were insulated properly.

“It’s the last thing that should happen,” Pachon said. “Without insulation, your heating costs go up and the building has a bigger carbon footprint, plus there’s condensation problems that show up years later with mould and mildew.

“Everyone knows they should insulate pipes properly — they just don’t do it.”

Ontario-based mould remediation specialist Graham Dewar said if conditions are right, mould can begin to grow in a few weeks, but it may take months or years to be visible.

“You won’t necessarily see it, but if it gets going, you’ll definitely smell it — that mustiness,” said Dewar, who was the senior project manager for a $23-million mould removal and repair job on a provincial courthouse in Newmarket, Ont.

“I’m a huge supporter of the Olympics and I know Vancouver is under tremendous pressure to meet a deadline — I know it’s a huge task, but if they aren’t fully insulating the pipes, they’re taking risks.

“It may or may not cause problems for the athletes, but long term, there’s the potential for condensation to build and that’s not going to be a good thing. I think they’re making a grave mistake.”

© Copyright (c) The Province